Epplix Expanded Polypropylene

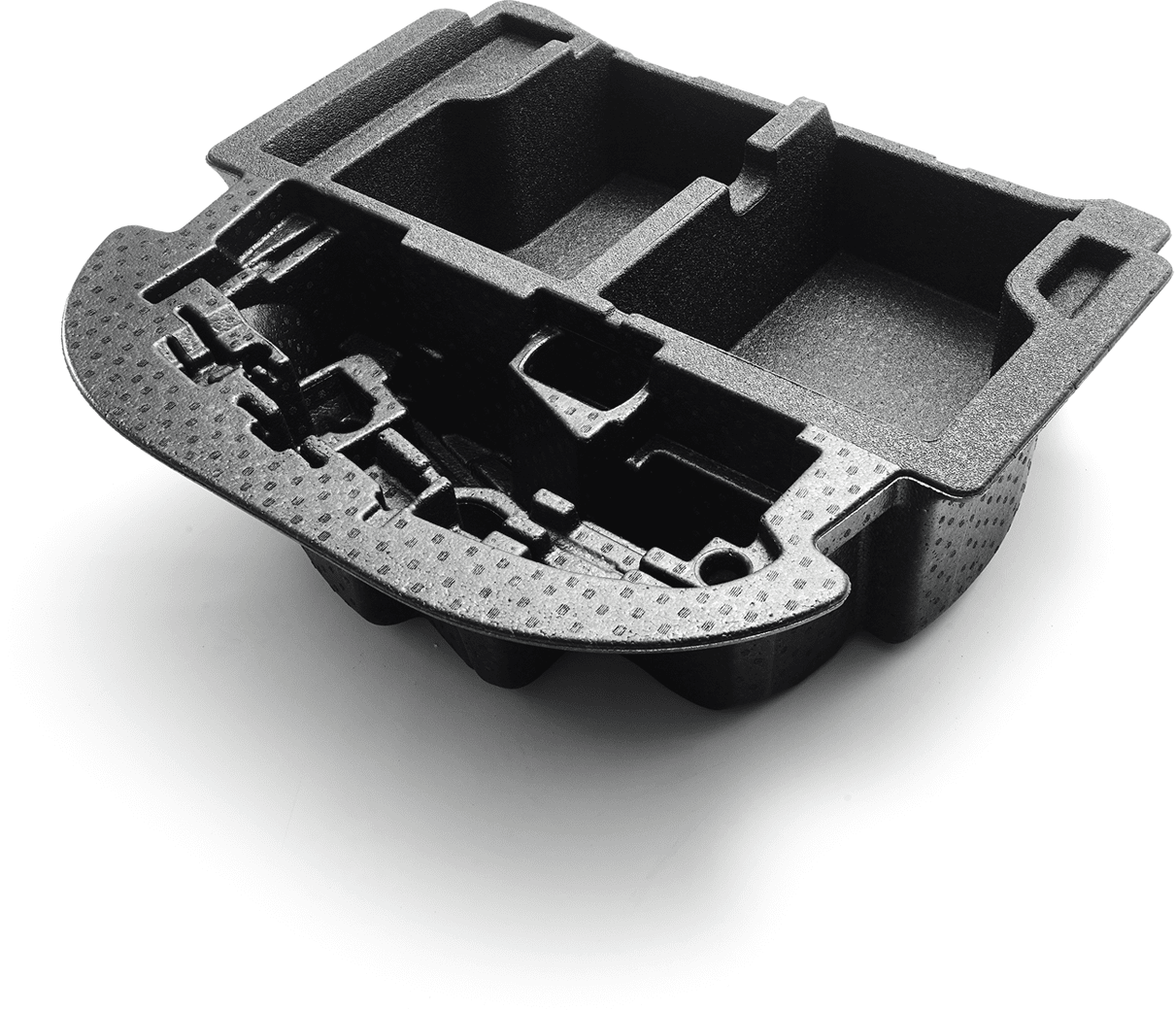

Epplix delivers Expanded Polypropylene (EPP) for smart applications in the rapidly changing Automotive, HVAC, Packaging & Transport, Domestic Appliance, Leisure and Marine industries.

Epplix EPP adds innovation to any of your products. Our beads are fully recyclable, lightweight, thermally stable and highly energy-absorbent. Epplix is a fast-growing company driven by its in-depth market knowledge and focus on research, innovation and new technologies.

Epplix Epp

Its unique combination of material properties ensures that Epplix EPP can be used for a whole range of applications. Epplix EPP provides ample opportunities for product innovations thanks to the following properties:

Strong

With its extremely high weight-to-strength ratio, EPP is widely used in the Automotive and Packaging & Transport industries. Epplix applications are becoming very popular in the Leisure and Marine industries.

Lightweight

In the Automotive industry, Epplix both helps increase safety and comfort levels and reduces weight and carbon emissions. Additionally, EPP applications help you cut down on production, assembly and transport costs.

Shock-absorbent

Epplix offers protection in transit. EPP products are increasingly becoming key components, such as bumper, in the construction of the passive safety systems used in trucks and other vehicles. Epplix energy-absorbent packaging complies with the highest industry standards and is used for medical products and other highly sensitive equipment that requires protection in transit.

Environmentally friendly

Epplix EPP is fully recyclable. The material is made exclusively of polypropylene and does not contain CFC or any other propellants. This makes it very easy to recycle.

Insulating

Epplix provides protection for temperature-sensitive products. Due to the insulating properties it is used in heating, ventilation and air-conditioning applications (HVAC).

Chemically resistant

Oil, grease and almost any other chemicals have virtually no effect on Epplix properties. Epplix provides a lightweight solution for environments exposed to these substances.

Noise-absorbing

Epplix strong noise-absorbing effect is designed for environments where a maximum impact is required with only a limited amount of space available – as in the Automotive and HVAC industries.

Epplix Grades

Epplix develops EPP beads on a customised basis. We aim to create the most effective recipes for the goals and requirements set by our customers. Our product is lightweight, flame-retardant, noise-insulating, shock- and impact-resistant and fully recyclable.

By continuously innovating and responding to new trends and developments, we provide the foundation that satisfies your and your customers’ requirements. Your problem represents an opportunity for us to develop innovative solutions together.

Grade B16

Epplix manufactures expanded polypropylene (EPP) for smart applications.

Beads are our core business. We have acquired many years of expertise and market knowledge related to moulding, research and innovation.

Epplix delivers easy-to-process, high-quality grades, offering fast delivery at competitive prices. We support you in the product development process. We can supply CNC-milled prototypes, advise you on matrix construction and measure your products using 3D technology. We supply to, and are partnered with, the Automotive, HVAC, Packaging & Transport, Domestic Appliance, Leisure and Marine industries. In a landscape where new applications and innovations are emerging constantly, Epplix is ahead of the latest trends and capitalises on innovative technologies.

Automotive

Climate Control

Packaging & Transport

Domestic Appliances

Leisure

Epplix as a partner

Automotive

Epplix is impact-resistant, extremely lightweight and helps you cut your assembly and production costs. Epplix is riding the wave of innovation in the Automotive industry.

Climate Control

Epplix is rigid, provides a high level of thermal and acoustic insulation and is insensitive to oil and chemicals. We provide more functionality using fewer components. Our recipes help to increase the efficiency of your products.

Packaging & Transport

Epplix saves costs and cuts down on waste as it can be used multiple times without presenting any risk to your product. E-commerce – where frozen or fresh products are delivered daily to consumers and businesses – is one of the

fast-growing markets using Epplix for its thermal packaging solutions.

Domestic Appliances

Examples of the domestic appliances for which our product is used include lightweight ironing boards (which improve the performance of state-of-the-art steam irons) and hoovers equipped with EPP bumpers (which reduce their weight and protect the home against damage). Epplix is rigid, provides a high level of thermal and acoustic insulation and is insensitive to oil and chemicals.

Leisure

One of the benefits of Epplix EPP is that it provides protection in helmets for practitioners of winter and mountain sports (including skiing, snowboarding and mountain climbing). Epplix® EPP is used in the lightweight aerodynamic protective covers for drone rotors.

Epplix as a partner

Serving as a partner between the market and moulders, Epplix aims to innovate together with all parties, tap new markets and explore new applications.

About

Epplix was created from a partnership with the moulding industry, which exhibits a growing need for market knowledge, new technologies and innovation.

As a fast-growing company, we invest heavily in research and development, and our brand-new production sites and facilities comply with the highest industry standards. With their solid market knowledge and expertise, the members of our team can quickly assist you with any product queries you may have.

We focus on finding the highest-quality components, customised to suit your specific requirements. We aim to be an industry leader in innovation and new applications, combining a firm focus on service with competitive prices. The industry is learning to respond more rapidly to new technologies, new products and new applications. Epplix uses its innovative solutions to provide you with the ingredients your business demands now, as well as contributing to future innovation. Read on and find out >